The Rise of Digital Twins: Revolutionizing Logistics and Beyond

Nowadays, we see more and more technologies being used in production and different technological areas. Robots, artificial intelligence – all of these are being used more and more every day, and there are even more new technologies on the way. But the most important thing is to keep track of them and apply them correctly in the production. Today we want to talk about digital twins. So what are digital twins, and how are they used? To find out more, read our article.

Digital Twin and its application

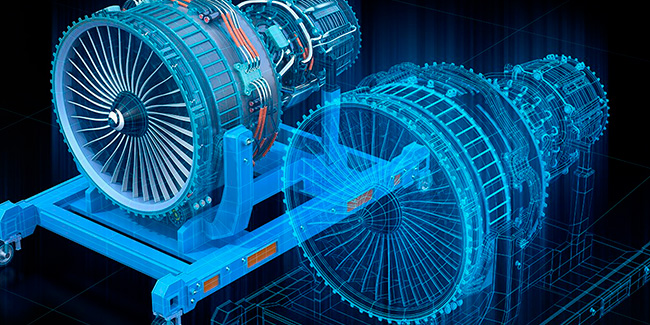

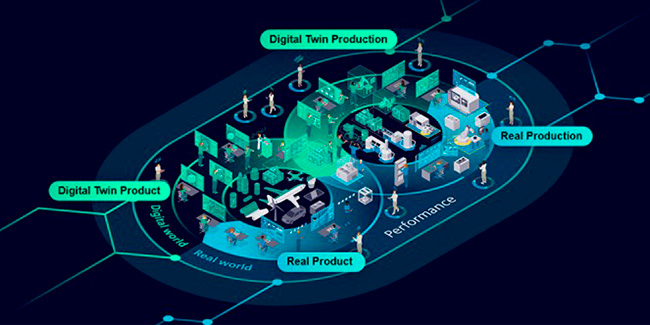

A digital twin is a virtual model that accurately represents a physical object or system. With a digital twin, it is easy to predict the performance of an object or system using special sensors. These sensors show the performance, which in turn allows us to analyze and optimize it. A digital twin is not just a simulation. It helps to understand the performance capacity of an object and creates a dynamic environment for in-depth study of the object or system itself.

Digital Twin Application In Warehouse and Logistics

The digital twin has changed the way we think about logistics in general, and warehouse management in particular. This technology allows simulating scenarios to improve warehouse efficiency and safety. For example, it becomes easy to plan the distribution of goods in the warehouse in real-time to optimize the use of space. Moreover, it can also prevent potential equipment failures. To understand digital twin better, let’s take a look at its benefits:

- Insights for warehouse management.

- Inventory Management.

- Improved Workflow.

- Boost Productivity.

- Strategy Creation.

- No Extra Costs or Risks.

- Better R&D.

As a result, using a digital twin, companies can save on downtime and maintenance costs. Digital twins are transforming logistics, and many companies are already using the technology.

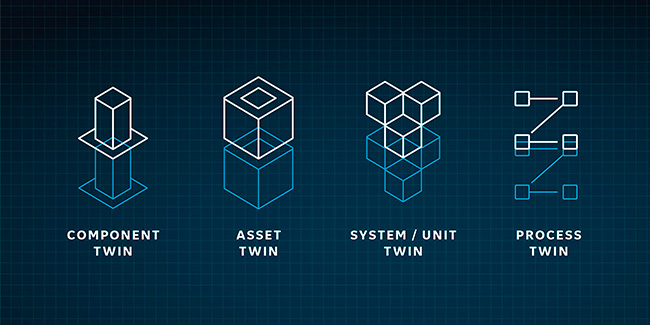

Types of Digital Twins

Depending on companies’ needs and requirements, there are different types of digital twins. Component twins represent individual system components while asset twins show how multiple components interact. On the other side, system twins illustrate entire systems and their asset interactions, and process twins, focus on optimizing complex processes and entire production lines or facilities.

Digital Twin Usage In Other Industries

Digital twins are not only used in warehouse management and logistics but also in other industries such as healthcare, i.e. medicine, vehicle manufacturing, aerospace, etc. These industries use digital twins because of their ability to manage complex systems and structures. For example, mechanical engineering uses twins to optimize vehicle production, while in healthcare, twins can be used to track patient health indicators. At the same time, it’s also used in power-generation equipment production, optimizing performance.

The Future Of Digital Twins

The future of digital twins. Today, resource-intensive industries are experiencing fundamental changes that are radically transforming their operating systems. They are helping with this transformation by integrating the physical and digital representation of assets, equipment, and objects. Digital twins are therefore an important part of this industrial reorganization.

When we talk about the future of digital twins, it is almost limitless, as more and more cognitive resources are spent using them. Digital twins are constantly developing. They are developing their skills and capabilities, which means that they will only be used more in other industries.

Introduct is all about finding new technological solutions for logistics, streamlining supply chains, and optimizing inventory management with cutting-edge IT solutions.

More Articles

Layoffs in Tech: What to Expect and How to Thrive in 2024 Layoffs in Tech: What to Expect and How to Thrive in 2024

In a rapidly changing IT world, everything has recently changed. And we're talking about tech layoffs. You probably heard that many IT companies and IT giant companies are cutting off tech jobs, and you're not alone. Did you know that 260, 000 tech workers lost their jobs in 2023?

AI in Crisis: Will the AI Bubble Burst? AI in Crisis: Will the AI Bubble Burst?

The development of artificial intelligence has brought many innovations to our world and many areas of people's lives. But is this really the case? Today, there are many controversial questions about AI. Recently, many potentially unstable moments have been discovered in relation to its work in different industries. Inefficient financial management, exaggerated expectations of AI, and possible options for further development are some of the key issues. Let's take a look at the development of artificial intelligence in recent years. The examples will allow us to see if the bubble is really bursting.